Brendon

Brendon How do you set up your take-off workflow for commercial iron roofing and cladding Project

Hi team,

I’m interested in how others structure their take-offs in zzTakeOff or similar when measuring commercial Iron roofs and wall cladding projects.

At the moment, I’m trying to streamline my workflow, and I’m unsure what the most efficient (and accurate) setup is.

Specifically:

- Do you create a new item for each specific detail (e.g., apron flashing, barge, ridge, internal/external corners, J-flashings, box gutter junctions, etc.) and then load the relevant materials into that item?

- For details that involve multiple flashing sizes, fixings, sealants, closures, and other bits and pieces, do you build these as assemblies under one detail? Or keep them separated?

- When measuring, do you apply the detail item directly to the roof plane/elevation area where it occurs, or do you run a separate linear take-off for each flashing type to maintain accuracy?

- How are you handling overlaps, laps, allowances, and waste factors within your take-off item—do you build these into the assembly, or adjust at the end?

- Any tips for naming conventions, grouping, or template structures that make it easier to repeat across similar projects?

Just looking to see how others manage their workflow so I can ensure I’m not overcomplicating something that could be more automated.

Appreciate any insights or screenshots of how you structure yours.

@Todd we should a working session Thursday during the normal advanced webinar with this if Brendon can attend?

Here is further information on what I think would be a good workflow if it's possible.

Note, i mainly do Commercial so most details will have 5 different type of flashings

So I was thinking something like this?

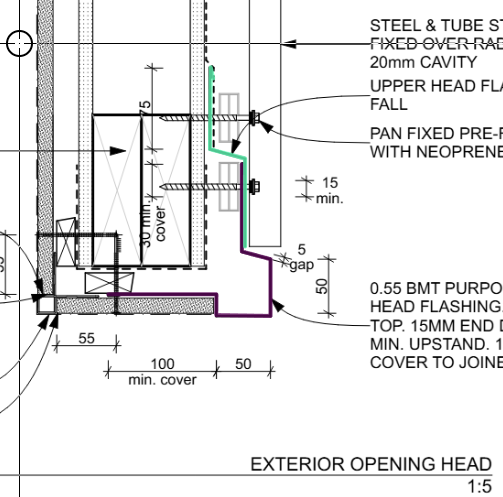

Find a Detail and measure the flashing up into a folder to keep it tidy.

The other plus side of this is if a contractor wants confirmation, we have allowances, we can send the marked-up details

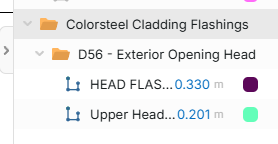

Then go to the elevations and Measure the locations of that detail, and somehow allocate all the flashing to that line.

Potentially has a report that picks the measure of the flashings to be presented, like

Item 1 - 0.330m Head Flashings - 6.725m

Item 2 - 0.201m Upper head Flashing - 6.725m